|

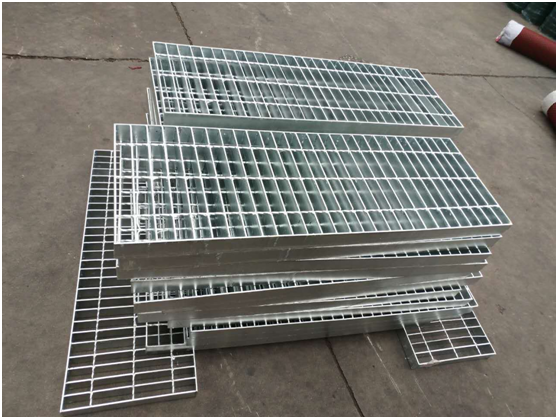

Galvanized Steel Grating

Collect

Galvanized steel grating is a versatile steel product formed by arranging loaded flat steel and cross bars at specific intervals in warp and weft. These components are welded together using a high-voltage resistance welding machine, creating the original plate. Further processing, including cutting, incision, hole opening, and edge wrapping, is done to meet customer requirements and produce the finished product. Types of Galvanized Steel Grating: Manufacturing Process: Galvanized steel grating can be categorized into pressure-welded and pressure-locked types based on the manufacturing method. Surface Shape: Galvanized steel grating can be further divided into tooth-shaped, flat type, I-type, and composite type plates, depending on the surface shape. Identification Method of Galvanized Steel Grating: (1) Flat Bar Center Distance: Differentiated by series: Series 1 has a center distance of 30mm; Series 2 has a center distance of 40mm; Series 3 has a center distance of 60mm. (2) Distance Between Centers of Crossbars: Series 1 has a distance of 100mm, and Series 2 has a distance of 50mm. Other specifications can be customized. (3) Flat Steel: Made of Q235A or stainless steel, with various types such as ordinary flat type, slip-resistant tooth type, and section I type. Common specifications include 205, 255, 253, 325, 405, 403, 505, 655, 756, 1008, 10010, and more. (4) Cross Bar: Made of round steel, twisted square steel, square steel, or hexagonal steel using Q235A or 304 stainless steel. Twisted square steel is made through wire drawing and twisting in a square die, with common specifications of 55, 66, 88mm, etc. Features and Usages of Galvanized Steel Grating: Features: High Strength and Light Structure: The strong mesh pressure welding structure ensures high load-bearing capacity and a lightweight structure, making it easy to handle and install. Durability and Aesthetics: Galvanized steel grating boasts a beautiful appearance and long-lasting performance. Usages: Galvanized steel grating finds extensive applications in various industries and sectors, including: Platforms, Walkways, and Trestles Ditch Covers and Manhole Covers Ladders and Fences Petrochemical Plants, Power Plants, Water Plants, Sewage Treatment Plants Municipal Engineering and Sanitation Engineering Projects It serves as an essential product in these fields due to its strength, versatility, and reliability.

|