|

Compound Steel Grating

Collect

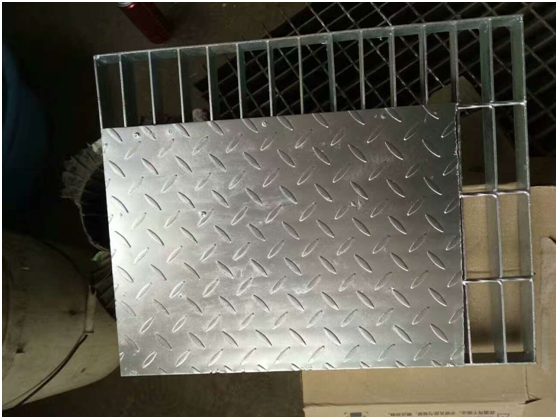

Compound steel grating is an innovative steel grating product that combines the load-bearing capacity of steel grating with a sealed checkered steel plate or steel mesh on the surface. It can be composed of various types of steel grating and industrial steel plates with different thicknesses. The most commonly used configuration is G323/40/100 steel grating as the base plate and 3mm checkered steel plate as the top plate, but other thicknesses like 4mm, 5mm, or 6mm can also be used. Features of Compound Steel Grating: High Strength and Durability: The combination of steel grating and checkered steel plate results in a product with superior strength, light structure, and excellent corrosion resistance, ensuring long-lasting performance. Aesthetic Appearance and Easy Maintenance: The compound steel grating's bright surface and self-cleaning ability make it easy to maintain. It prevents accumulation of rain, snow, and water, making it ideal for various applications. Versatility: The compound steel grating provides excellent ventilation, lighting, heat dissipation, slip resistance, and explosion-proof properties. It is also easy to install and disassemble. Applications of Compound Steel Grating: Compound steel grating is widely used in various applications. It often utilizes steel grating as the base plate, and when a double mesh panel is created by connecting steel mesh to the front or bottom of the steel grating, it prevents small pieces from falling through. The double mesh panel finds applications in granaries, restaurants, and warehouses, acting as a barrier against small animals like mice. Additionally, compound steel grating is extensively employed in power plants, paper-making plants, cement plants, walkways, trestles, ditch covers, manhole covers, ladders, and other areas requiring enhanced load-bearing and safety features. Its versatility and benefits have led to its increasing popularity in recent years.

|